From August 13 to 16, 2024, the 27th Essen Welding & Cutting Fair was grandly held at the Shanghai New International Expo Centre. As a top-tier event in the global welding field, the Essen Fair brings together leading welding technology, equipment, and service providers from around the world.

As a pioneer in popularizing collaborative robots and exploring new application scenarios, FAIRINO has initiated the extensive application of collaborative robots in the welding industry. In the first half of 2024, FAIRINO's deliveries in the welding market exceeded 1,000 units, securing a leading position in the collaborative robot welding market. At this exhibition, FAIRINO’s welding solutions appeared frequently across numerous booths, making it the "star product" of the fair. Let’s take a quick look at the exciting highlights from the event!

01: Powerful Welding Solutions

The automated welding equipment integrated with FAIRINO collaborative robots not only quickly adapts to major global welding machine brands but also offers flexible combinations with extension axes, positioners, force sensors, and more. It supports various welding processes, including direct welding, section welding, corner welding, and multi-layer/multi-pass welding.

The open development platform provides our partners with more convenience and possibilities. Users can flexibly develop operating systems based on actual needs to meet the special requirements of different welding scenarios. Attendees at the exhibition were highly impressed by the workstation’s open compatibility and user-friendly, powerful features. The booth was bustling with continuous inquiries and high popularity.

02: Simple Yet Powerful

The FAIRINO AIR Lab's natural language control system, developed based on large model training, enables collaborative robots to automatically generate code instructions from natural language commands. This further frees users' hands, making robot operation more straightforward and intuitive. The no-programming automatic welding platform, equipped with a 3D camera and offline simulation capabilities, allows for genuine no-teaching, no-programming, and automated operation in just three simple steps. Ordinary workers plus collaborative robots create a new standard in welding.

In addition to ongoing software upgrades, FAIRINO remains committed to creating a more open and compatible ecosystem. We have introduced an application model combining collaborative robots, FAIRINO technology packages, and partner ecosystem modules. This model fully supports ROS/ROS2 platforms and is compatible with various communication methods, including IO, 485, TCP/IP, ModbusRTU, and ModbusTCP. It also supports multiple SDKs, such as C#, C++, and Python, allowing seamless integration with other devices and systems. This comprehensive and efficient solution meets the in-depth development needs of integrators and provides users with a more effective welding industry solution.

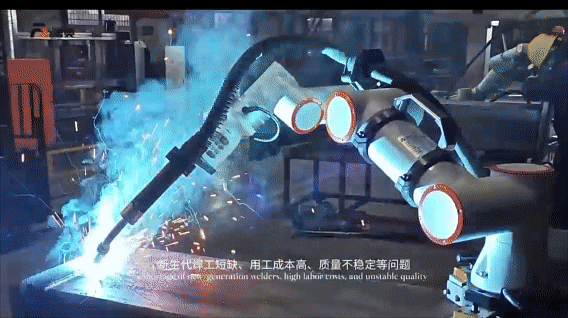

03: Intelligent Manufacturing Upgrade – Welding the Future

The automated welding equipment integrated with FAIRINO collaborative robots features a control cycle of just 1ms, allowing for precise control. It can handle both fine welding points and complex welding paths with ease. The setup is simple and drag-and-drop, with a learning curve of just 2 minutes, making it accessible even for beginners who can achieve results comparable to seasoned welders. One ordinary worker can operate 3-4 machines simultaneously, increasing efficiency to 2-3 times that of manual welding, effectively alleviating the shortage of welders. With a 3D camera, real-time weld seam deviation compensation ensures consistency in welding operations.

04: Conclusion

With the advancement of Industry 4.0, welding technology continues to evolve. Automation and intelligence are the inevitable trends in the welding industry. FAIRINO will continue to support the "smart" upgrade of the welding industry with flexible robot products and intelligent solution design, making collaborative robots the “best partner” in welding and opening a new era of intelligent welding.

Fill out the form and you will get

Fill out the form and you will get