From everyday furniture to national heavy machinery, welding has always been a key process in the manufacturing industry, especially in shipbuilding and steel structure industries. However, traditional welding methods often struggle to balance efficiency, quality, and flexibility when faced with challenges such as large components, non-standard parts, difficult-to-move workpieces, a wide variety of welding pieces, and high costs for production layout modifications. As a "Collaborative Robot Popularizer and New Scenario Application Pioneer," FAIRINO, guided by the philosophy of "AI + FAIRINO = REALITY," has deeply understood the pain points of the welding industry and is committed to reshaping the welding experience with AI. To this end, FAIRINO has launched the new generation FR3WML and FR3WMS collaborative robots, specifically designed for welding scenarios, offering the following core advantages:

► Lightweight and Flexible: Weighing ≤11kg, they can be lifted with one hand, making them easy to deploy and capable of handling various complex working environments.

► Technical Features: The end can rotate 360°, adapting to welding needs at different angles.

► Stable and Reliable: With an optional IP65 protection rating, they are dustproof, oil-resistant, and protected against water spray, ensuring stable operation in harsh environments.

01 FAIRINO AIRLab

Makes Welding Simpler

The FAIRINO AIRLab is equipped with self-developed vision and planning algorithms, enabling AI-interactive control of equipment and integrating AI into the vision recognition process to efficiently complete welding tasks. The vision system offers high positioning accuracy and fast recognition efficiency. The AIRLab supports multiple programming languages, including C++, C#, Python, ROS, and TCP/IP, providing developers with diverse options. Users can perform secondary development based on their needs to expand the robot's application functions.

Powerful Weld Seam Recognition: Achieves automatic recognition of weld seams with or without models through point cloud algorithms.

No Programming or Teaching Required: Can preemptively identify welding difficulties, eliminating the need for manual modeling and improving welding preparation efficiency.

FAIRINO is committed to building a more open and compatible ecosystem, offering an application model that Robot+, FAIRINO Packages+, and Partner Ecosystem Modules. This model can seamlessly integrate with other equipment and systems, fully meeting the deep development needs of integrators and providing users with more comprehensive and efficient welding industry solutions.

02 FAIRINO Welding ProcessPackage

Opens a New Chapter in Intelligent Welding

FAIRINO robots fully understand the needs of specific welding scenarios and have developed a more comprehensive, easier-to-operate, and smarter-to-store FAIRINO welding process package. The automated welding equipment integrated with FAIRINO collaborative robots can quickly adapt to global mainstream welding machine brands and flexibly combine with extension axes, positioners, force sensors, etc. It supports various welding functions such as swing welding, arc tracking welding, wire positioning, and welding interruption recovery, as well as multiple welding processes like straight welding, segment welding, fillet welding, and multi-layer multi-pass welding.

① Swing Welding

FAIRINO robots support various swing shapes, including triangular wave, vertical L-shape, triangle, circle, oblique zigzag, and sine wave.

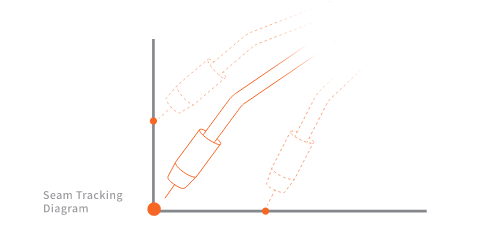

② Arc Tracking

When welding grooves such as right angles, U-shapes, and V-shapes, the robot calculates the position relationship between the welding gun and the groove center based on the welding current and voltage information after arc initiation, compensating for weld deviations in real-time to ensure precise weld position and stable welding quality.

③ Wire Positioning

Wire positioning detects the actual position of the workpiece in the robot's coordinate system by detecting changes in the electrical signal when the wire contacts the workpiece surface. After teaching the positioning path, the robot automatically finds the workpiece surface boundary. When the wire touches the workpiece surface, a voltage signal change occurs, and the welding machine communicates this signal back to the robot, which records the boundary position.

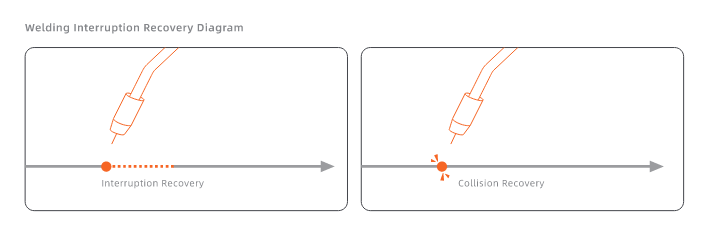

④ Welding Interruption Recovery

This function is used when welding is interrupted due to operator intervention, collisions, or arc breaks. The robot can re-ignite the arc from the interruption point and continue the welding task. When re-igniting, the robot automatically retreats a specified distance along the welding direction to overlap with the previous weld, ensuring welding quality.

03 FAIRINO Lightweight Push-Pull Welding Torch

Ensures Excellent Welding Quality

FAIRINO welding robots are equipped with lightweight push-pull wire welding guns, capable of adapting to long-distance wire feeding needs. Whether in flat, vertical, or overhead welding positions on ship hulls, they ensure stable wire feeding, significantly improving welding efficiency. Uniform and stable wire feeding effectively guarantees welding quality.

► Ultra-Long Wire Feeding: Wire feeding hose extended to 20 meters.

► Goose Neck Quick Change: Simple operation for quick replacement.

► Compact Design: Weighs ≤1.1KG, lightweight and convenient.

► Wide Application: Suitable for long-distance and narrow-space welding scenarios in shipbuilding, bridge construction, and steel structures.

04 Jointly Opening New Horizons

FAIRINO Accelerates Overseas Market Expansion

The exceptional performance of FAIRINO welding robots not only brings efficient solutions to the domestic welding industry but also serves as a powerful tool for FAIRINO's overseas market expansion. With their stability and ease of use, FAIRINO welding robots and their supporting equipment have gained widespread recognition globally. Currently, FAIRINO's robot business covers more than 40 countries and regions, including Germany, Mexico, Russia, Japan, and South Korea, establishing deep cooperation with global industry leaders. Particularly in the welding sector, FAIRINO closely collaborates with leading enterprises such as China Construction Steel Structure and Honglu Steel Structure, promoting the intelligent transformation and high-quality development of the welding industry through welding software process packages and one-stop solutions.

By combining local operations with global resources, FAIRINO quickly responds to the needs of clients in different regions, further accelerating its globalization process. FAIRINO integrates top global technical resources, collaborating deeply with the MIT team (TutoIntelligence) to drive innovation and application of collaborative robot technology. Additionally, FAIRINO has formed a strategic partnership with the renowned American welding machine brand Everlast to develop high-performance welding solutions. Everlast is known for its innovative technology, reliable quality, and excellent cost-performance ratio in the global welding industry.

AI Meets FAIRINO, Reality Starts Here. Looking ahead, in the welding field, collaborative robots will enter more factories with their lightweight and simple advantages, opening up vast opportunities for smart industrial factories. FAIRINO continues to deepen its presence in the welding industry, driving intelligent manufacturing and industrial upgrading, and illuminating the singularity of global industrial automation and intelligent transformation.

Fill out the form and you will get

Fill out the form and you will get